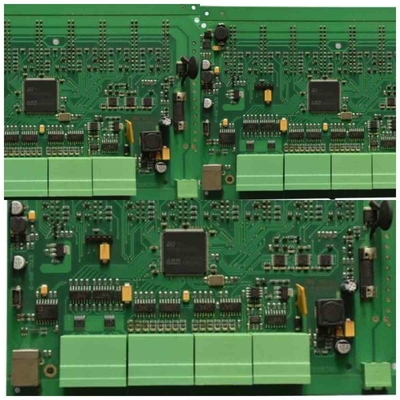

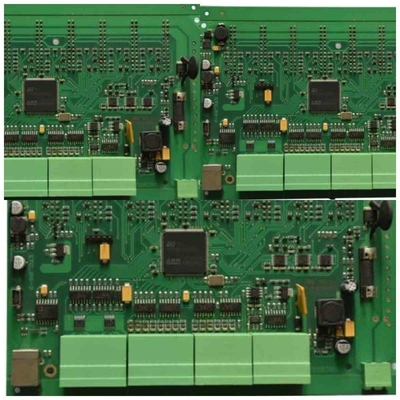

Green PCBA Printed Circuit Board Assembly Electronic Components Electronic Devices

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| PCB Layer | PCB Assembly Electronic Components | Solder Mask | Green |

|---|---|---|---|

| ApplicationIndustrial Control Products | Industrial Control | Special Requirement | PCB Assembly Electronic Components |

| High Light | Green PCBA Printed Circuit Board Assembly,Electronic Components Printed Circuit Board Assembly,Solder mask electronic pcb assembly |

||

PCBA PCB Assembly Assembled PCB Electronic Components Electronic Devices

PCB Assembly Electronic Components

Electronics are an integral part of our daily lives. Everything from our smart phones to our cars includes electronic components. At the heart of these electronics is the printed circuit board, also known as a PCB.

![]()

Most people recognize printed circuit boards when they see them. These are the small green chips covered in lines and copper parts you'll find at the heart of gutted electronic devices. Made with fiberglass, copper lines and other metal parts, these boards are held together with epoxy and insulated with a solder mask. This solder mask is where that characteristic green color comes from.

An advanced circuit board won't be able to give its functionality until components are mounted on it. A PCB with components mounted on is called an assembled PCB and the manufacturing process is called PCB assembly or PCBA for short. The copper lines on bare board, called traces, electrically link connectors and components to each other. They run signals between these features, allowing the circuit board to function in a specifically designed way. These functions range from the simple to the complex, and yet the size of PCBs can be smaller than a thumbnail.

The PCB assembly process is a simple one, consisting of several automated and manual steps. With each step of the process, a board manufacturer has both manual and automated options from which to choose.

FAQ:

Q1:Are you a factory or trade company?

A: Yes, we are the factory, we have independent quick turn prototype PCB manufacturing & big volume PCB production lines.

Q2:What kind of PCB file format can you accept for production?

A: Gerber, PROTEL 99SE, PROTEL DXP, POWER PCB, CAM350, ODB+(.TGZ)

Q3:Will our PCB files be checked.

A: Yes. Your data will be checked by our Engineers Team. If we find any technical issues or have any inquires, we will contact you and solve the problems together.

Q4: Does our product will be tested before shipment.

A: Yes. We could provide Function Circuit Testing if you provide us the testing methods.

Q5: Do you provide PCB Assembly services, too?

For heavy goods more than 300kg, we may ship your PCB boards by ship or by air to save freight cost. Of course, if you have your own forwarder, we may contact them for dealing with your shipment.